High Pressure Purification

At Nuvair, we custom build high-pressure gas filtration systems at our California production facility to your exact specifications.

Proper filtration requires consideration of many conditions such as compressor size and output in cubic feet per minute (CFM) or liters per minute (L/min), ambient temperature and humidity, compressor type and the amount of oil/condensate that will need to be removed by the filters, required filter life and finally, and desired purity of the gas.

Nuvair can size your filtration system to meet any quality standard using our 15-inch, 25-inch or 35-inch towers. Larger systems can offer longer filter life, better gas quality, and a cost savings on the filters. This is done by using less expensive filter media for drying and extending the life of the more expensive final filter with active carbon and carbon monoxide (CO) catalyst.

Consider Your Requirements

Before calling us to discuss your filtering requirements, please consider these options:

APPLICATION

What gas will the filtration system produce?

- Industrial Air

- Breathing Air

- Nitrogen

MOUNTING

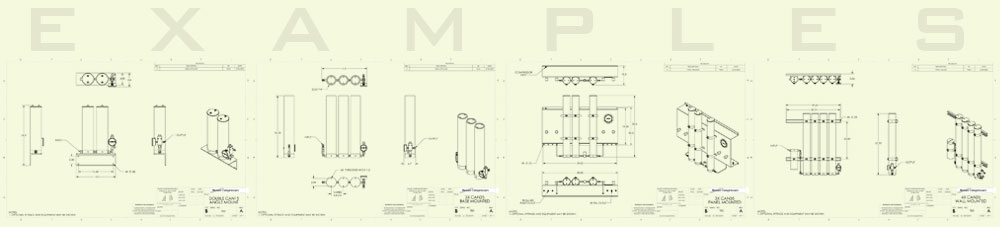

Because we custom make our filtering systems, we offer the following mounting configurations (click below to view example mounting schematics):

FILTER TOWER SIZE & NUMBER

We can fabricate a many different types and sizes of gas filtration systems:

- 15-inch Filter Towers

- 25-inch Filter Towers

- 35-inch Filter Towers

- 1–5 Towers in Series

MAXIMUM OPERATING PRESSURE

Most filtering systems can be designed with two maximum operating pressures. Which will match your gas system requirements?

- 5000 psi

- 6000 psi

SERVICE CYCLE

More filters—and larger filters—increase a gas filtration system service cycle (the time between filter element changes). Filter element life is based upon the quality of the source gas (the gas entering the system). Contaminates like moisture and particles greatly reduce filter element life.

OXYGEN COMPATIBLE AIR

If you require OCA (oxygen compatible air) output, we can design a gas filtration system to fit your technical gas needs.

Please call or email Nuvair sales to discuss and design your new high pressure gas filtration system.