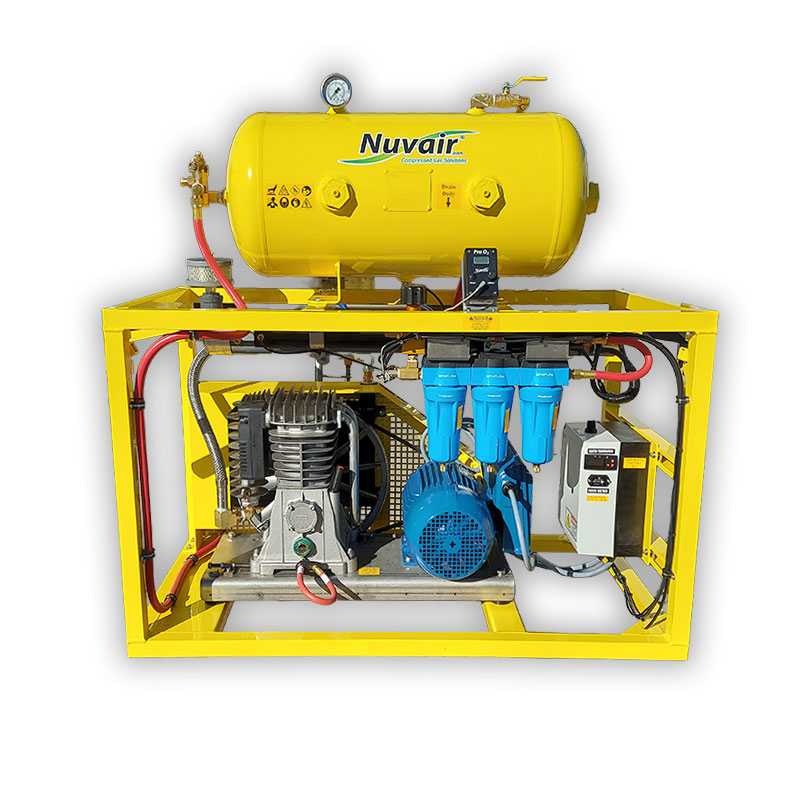

Traveler HP Portable Nitrox Generating System

The Nuvair Traveler HP efficiently and cost-effectively produces nitrox using gas or electric power, without the hazards or expense of pressurized oxygen blending. Supplies air or generates enriched air nitrox up to EANx40 at 3600 psi (248 bar).

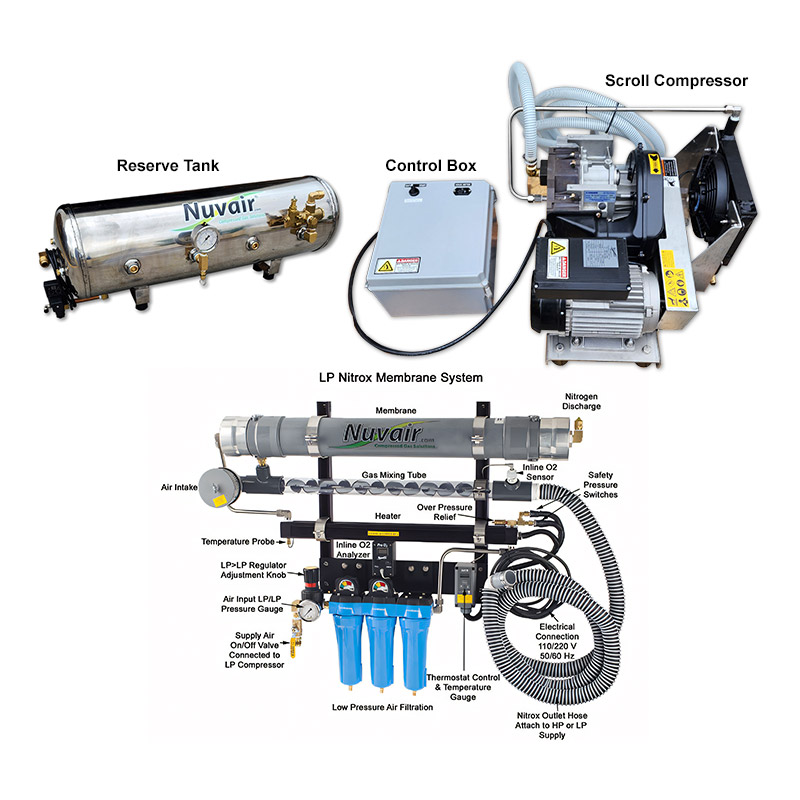

The Nuvair Traveler HP nitrox system allows for efficient and cost-effective nitrox production using gas or electric power, without the hazards or expense of blending with stored high pressure oxygen (O2). Instead, the system uses a semi-permeable membrane to produce nitrox from air. A portion of the nitrogen in air is separated out, leaving an oxygen-rich nitrox mixture. This nitrox mixture can be pumped up to a maximum pressure of 3600 psi (250 bar) when filling scuba cylinders.

The nitrox membrane requires a low pressure (LP) air source to make nitrox. High pressure (HP) air from scuba cylinders or storage tanks—along with a regulator—can be used to supply this LP air to the membrane system. Simple-to-operate, reliable and versatile, without the hassles or hazards of oxygen partial pressure blending. It is also portable and lightweight, making for easy transport.

The Traveler is designed to fill scuba-sized cylinders, not larger storage tanks.

Features

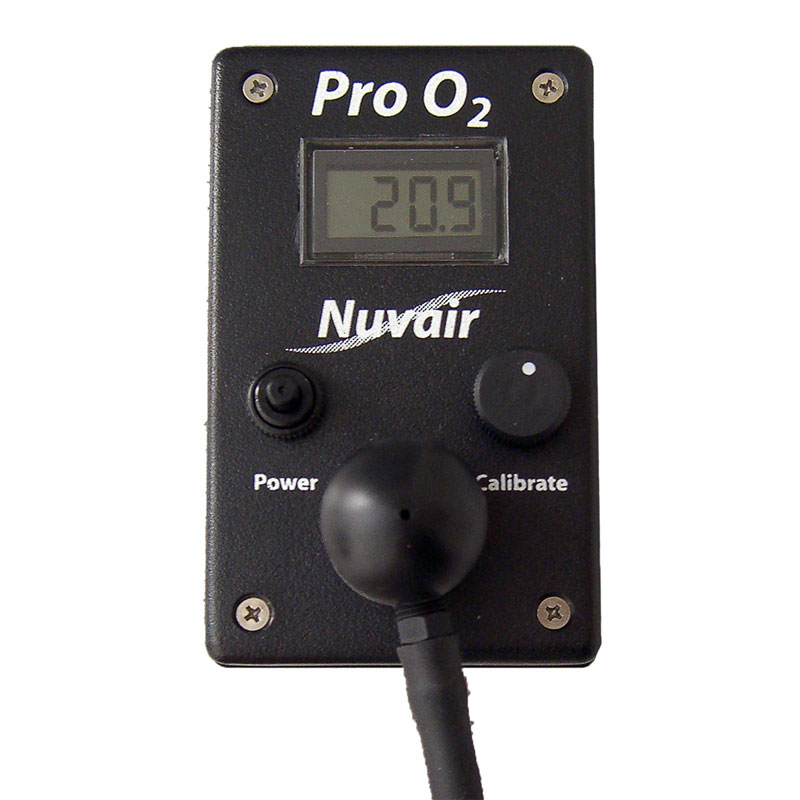

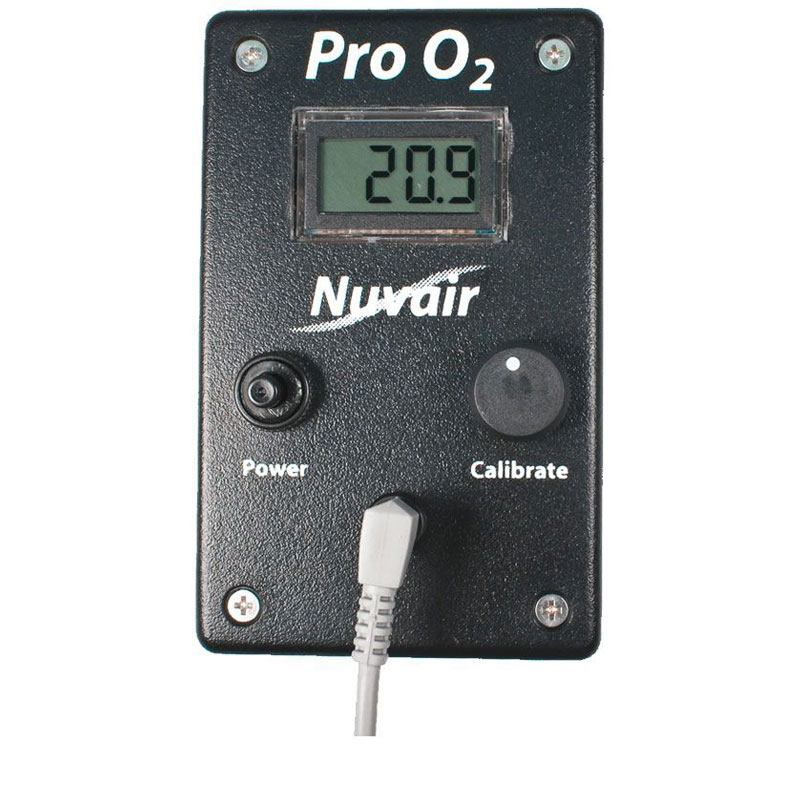

- 6 CFM nitrox membrane system with oxygen analyzer

- Electric (single/three phase) or gas powered

- HP compressor pumps air to 4500 psi (310 bar) and nitrox to 3600 psi (248 bar)

- Rigid powder-coated welded aluminum frame

- Static mixing tube and air intake filter

- Produces its own high pressure supply air**

Advantages

- Pump HP air or nitrox containing 21-40% oxygen

- Lower costs, less hassles and hazards compared to O2 blending

- Can use HP air from scuba cylinders to make nitrox

- Simple to operate, reliable and versatile

- Portable and lightweight for easy transport

Options

- Automatic HP condensate drains

- Automatic fill pressure stop

- Automatic high temperature shutdown

- Stainless steel compressor frame

- Hour meter

** Using two scuba-sized tanks, one tank can provide high pressure air for nitrox generation and the second tank is filled with the nitrox produced.

Motor Options

| 115 V / E1 / 50 Hz | 12 A SKU 7051.0-HP |

| 208-230 V / E1 / 60 Hz | 17 A SKU 7051.1-HP |

| 208-230 V / E3 / 60 Hz | 12 A SKU 7051.2-HP |

| Membrane Operating Pressure | 90-165 psi (6-11 bar) |

| Membrane Supply Air Volume | 4-11 SCFM (113-312 L/min) |

| Membrane Optimum Temperature | 110 ± 5°F (43° ± 3°C) |

| Nitrox Charging Rate | 3.4-4.2 SCFM (95-119 L/min) |

| Nitrox Fill Time* | 20-25 min |

| Power - Electric | 3-4 hp (2.2-3 kW) |

| Power - Gas | 5.5 hp (4 kW) |

| Dimensions (L x W x H) | 51 x 16 x 22 in (130 x 41 x 56 cm) |

| Weight | 134-140 lb (61-64 kg) |

* Single 80 cu ft cylinder from 500 to 3000 psi (34 to 207 bar).

OTHER PRODUCTS YOU MIGHT LIKE