LP560ME Marine Nitrox Generator

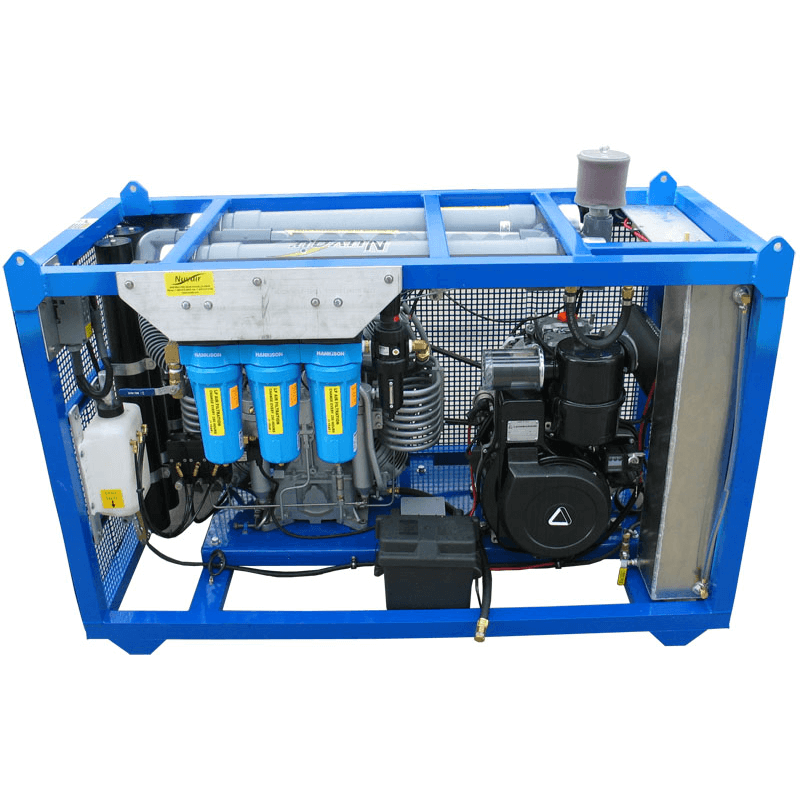

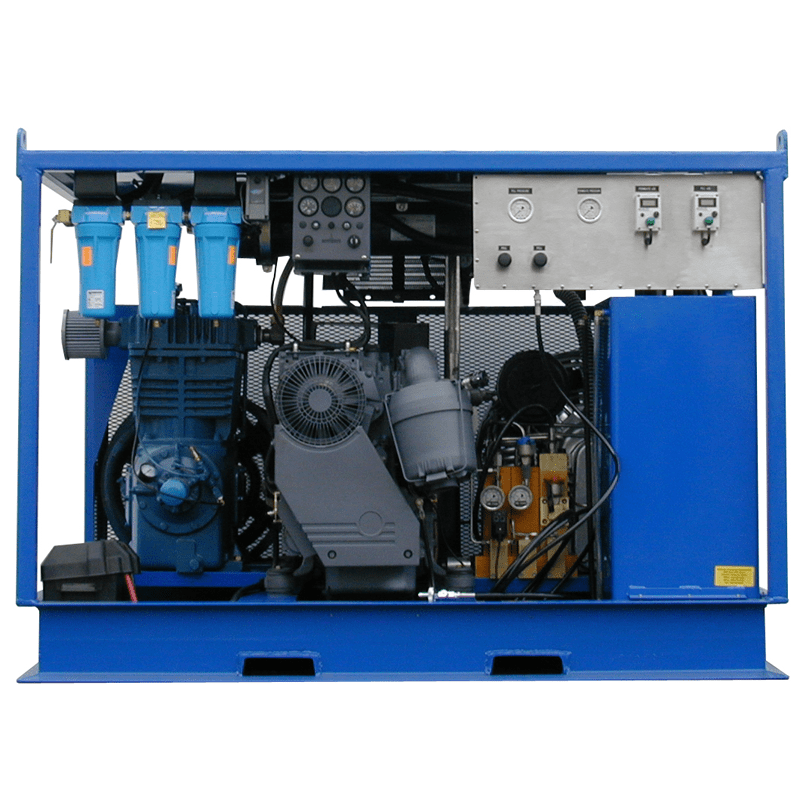

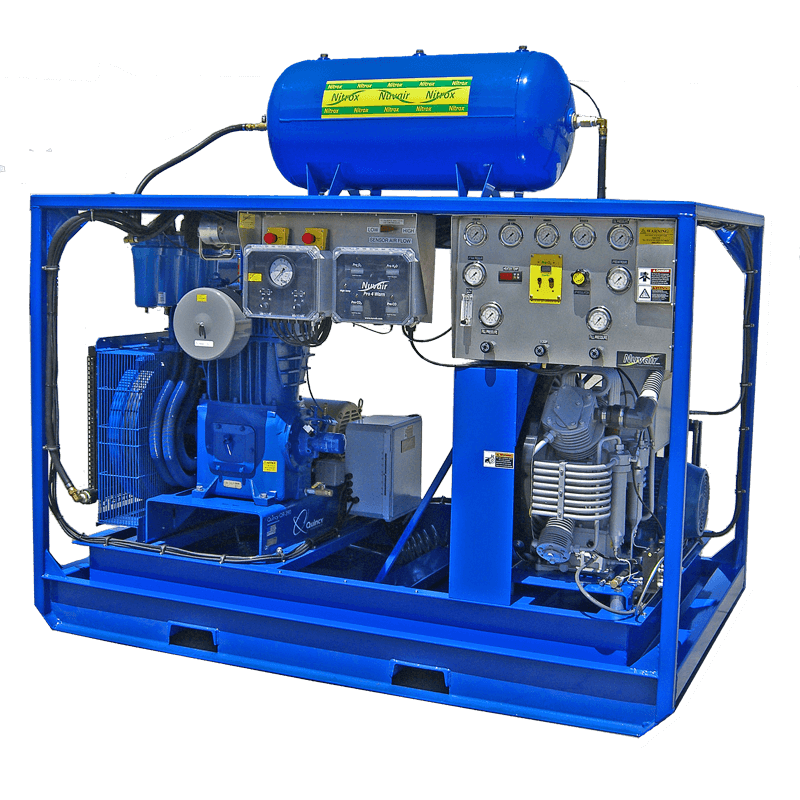

The LP560ME Marine Nitrox Generator™ uses a rotary screw low pressure (LP) compressor, air/oil aftercooler, (optional) refrigerated air dryer, and filtration to provide the membrane system with a source of clean, pressurized feed air for separation. The air is filtered to CGA Grade D or better air quality prior to entering the wall-mounted membrane system so it will not damage or plug the membrane fibers. Specifications for Grade D air are provided in the Operational Manual appendix.

The LP560ME membrane system is rated for a maximum feed air pressure of 300 PSI (21 bar) and has been configured to work well with the 175 PSI (12 bar) maximum pressure delivered by the LP compressor. A back-pressure regulator is used to adjust the amount of air the screw compressor produces to meet the appropriate levels for various O2% nitrox production. The air is then heated to a temperature that provides stability over a wide range of ambient conditions, is optimal for membrane permeation, and prevents moisture condensation.

The nitrox system allows for efficient and cost-effective nitrox production using electric power, without the hazards or expense of partial pressure blending with stored high pressure oxygen (O2). Instead, the system uses a semi-permeable membrane to produce nitrox from air. A portion of the nitrogen in air is separated out, leaving an enriched air nitrox mixture. Produces 22-40% enriched air nitrox or can also pump air.

Features

- Nuvair Nitrox Membrane System with two (2) oxygen analyzers

- Automatic shutdown for high pressure and temperature

- Automatic condensate drains

- Refrigerated air dryer for long filter life

- Hankison LP filtration for membrane system

- Microprocessor control or manual control for managing pressure, temperature and maintenance

Advantages

- Simplest, most cost-effective nitrox system available

- Supply LP air or nitrox containing 21-40% oxygen

- None of the costs, hassles, or hazards of oxygen blending

- Systems to fit most HP compressors

- Rotary screw LP compressor provides quiet operation and low maintenance

- Made to install below deck In hot engine rooms

- Compact size

Specifications

| Physical Specifications | Height Width Depth Weight Horsepower |

49.5 in (126 cm) 27 in (69 cm) 48 in (122 cm) 685 lb (311 kg)* 20 hp (15 kW) |

|---|---|---|

| Full Load Amps | 440 V / E3 / 50-60 Hz 400 V / E3 / 50 Hz 230 V / E3 / 50-60 Hz |

33 A 38 A 64 A |

| LP Compressor | Capacity @ 175 psi | 60 CFM (1700 L/min) |

| Membrane Input | Operating Pressure Supply Air Volume Optimum Temperature |

90-175 psi (6-12 bar) 13-60 SCFM (354-1700 L/min) 110 ±5°F(43 ±3°C) |

| Rated to Supply | FAD for 40% Oxygen FAD for 36% Oxygen FAD for 32% Oxygen |

20 CFM (560 L/min) 25 CFM (707 L/min) 34 CFM (970 L/min) |

* Model weight varies depending on electric motor type.

Please specify voltage and hertz required when ordering.